Perforated Panel Façade - Walker West Music Academy

Owner: Walker West Music Academy

Architect: Cuningham Group Architecture, Inc.

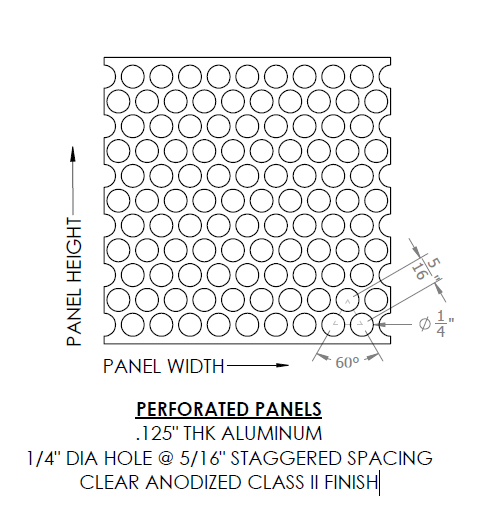

Product: Altair Perforated Panels

The Challenge- Orchestrating the Perfect Metal Melody

The Walker West Music Academy renovation sought to transform the building’s exterior into a vibrant expression of its musical heritage. The design called for a custom perforated panel façade to be fabricated and installed within the buildings existing masonry structure and mechanical systems.

Key challenges included:

- Integrating the new perforated panel façade around existing light fixtures, gas piping, and signage.

- Designing all structural supports and attachments to the existing masonry within IBC 2012 and ASCE 7-10 wind load standards.

- Maintaining high visual and dimensional precision across 30 custom aluminum perforated panels, each with a detailed perforation pattern.

- Developing and engineering all connection points for panels, corners, and signage supports.

The Solution- A Metal Masterpiece ft. a Perforated Panel Façade

To achieve the architect’s vision while meeting structural and code requirements, StellarCraft developed a comprehensive engineering, fabrication, and installation approach—integrating advanced design detailing, material control, and field coordination.

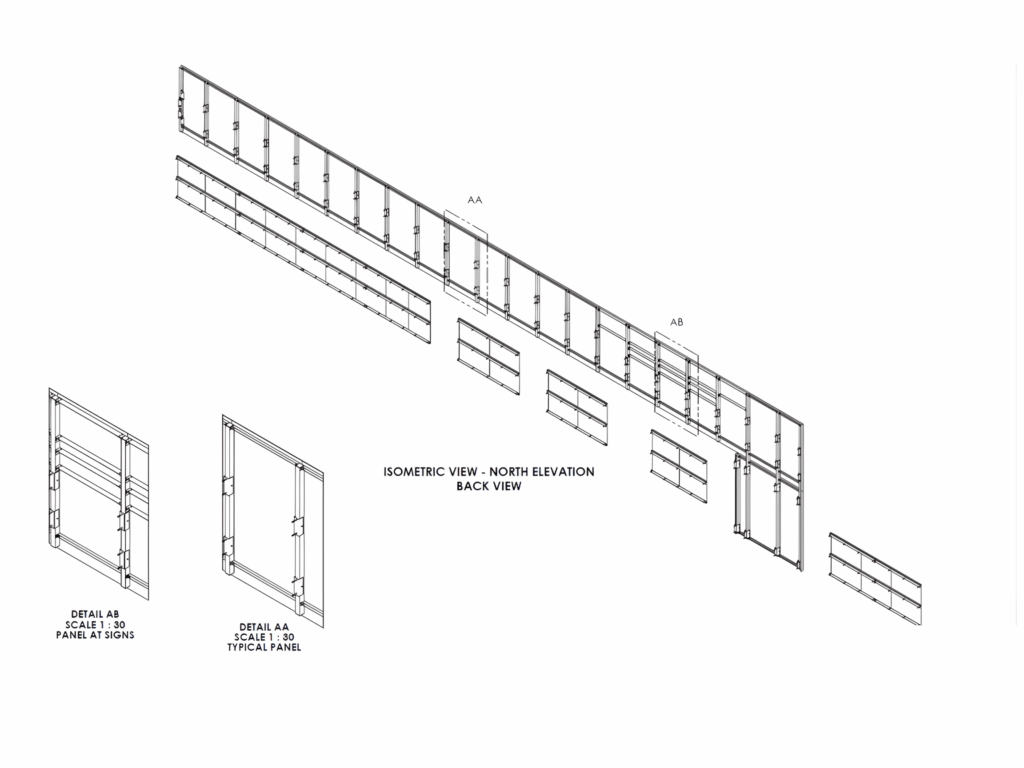

1. Structural Support Framework

StellarCraft engineered a custom tube and plate framework designed specifically for attachment to the existing masonry façade.

Key components included:

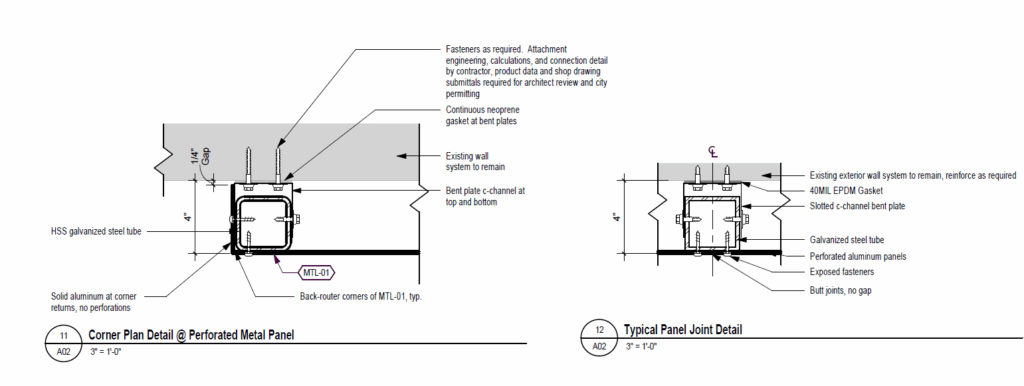

- HSS galvanized steel tubes forming the primary structural backbone. Vertical supports were constructed from 3″ x 0.25″ square tube, paired with 1.5″ x 0.125″ horizontal members to deliver structural stability and clean alignment across the façade.

- Bent C-channel plates at both top and bottom panel edges for uniform load transfer.

- Continuous neoprene gaskets and 40MIL EPDM seals to isolate dissimilar metals and manage thermal movement.

All connections were designed for ASD wind loads of 21 PSF at corner zones and 18 PSF at typical zones.

Detailed engineering calculations, anchor load tables, and connection drawings were produced and submitted to Rice Engineering and Cuningham Group for review and city permitting.

Anchorage was achieved with ICC-approved wedge anchors (Hilti, Powers, Redhead, or Simpson) per ASTM C90 standards for concrete masonry. Anchor embedment depths, spacing, and torque were verified in the field to match engineering specifications.

2. Panel Fabrication and Material Engineering

Each of the 30 façade panels was precision fabricated from 11GA aluminum (3003-H14), with a ¼-inch diameter perforation pattern on 5/16-inch staggered centers, terminating flush at all edges.

The panels were finished in a clear anodized Class II coating to ensure long-term corrosion resistance and consistent surface reflectivity.

Design and fabrication highlights:

- Corner detailing: Solid aluminum returns replaced perforations to enhance rigidity and maintain clean visual edges.

- Back-routered bends: Used to create seamless transitions and eliminate visible seams at corner joints.

- Panel deflection: Limited to L/60, with framing deflection capped at L/180 per design standards.

Material alloys:

- Structural tubes: 6061-T6 aluminum

- Bent shapes: 5052-H32 aluminum

- Fasteners: 300-series stainless steel, condition CW, Fy = 65 ksi, Fu = 100 ksi

3. Precision Assembly and Connection Design

The perforated panel façade required unique connection types—including panel clips, corner tube clips, and signage brackets—all custom-designed and fabricated by StellarCraft.

To ensure proper field installation:

- All assemblies were test-assembled in the shop before shipment.

- Components were labeled, sequenced, and packaged for installation order.

- Full bearing shims were used to maintain consistent spacing and support load transfer.

- Butt-joint, zero-gap panel connections achieved a seamless surface appearance per architectural specifications.

- Field coordination was critical. StellarCraft worked closely with the general contractor to verify clearances for all light fixtures, gas lines, windows, and signage attachments.

Fastening systems utilized stainless-steel self-drilling screws (ELCO BI-FLEX or equal) and Grade 5 bolts with engineered diameters and spacings.

Thermal isolation and galvanic corrosion prevention measures were built into each connection, ensuring long-term durability.

4. The results- sound craftsmanship

The completed perforated panel façade transformed the Walker West Music Academy into a striking architectural landmark.

Aesthetic Achievement:

The perforated panels create a dynamic interplay of light and shadow that visually enhances the Academy’s musical heritage.

Structural Integrity and Longevity:

The façade system meets all IBC 2012 and ASCE 7-10 code requirements, ensuring wind load resistance, thermal performance, and long-term durability through proper material selection and corrosion control.

Fabrication Precision:

Over 30 custom aluminum panels and unique support connections were executed to exacting tolerances, demonstrating StellarCraft’s capacity for technical fabrication and multidisciplinary coordination.

Seamless Integration:

The new perforated panel façade overlays the existing masonry without compromise, maintaining accessibility to existing utilities while enhancing the building envelope with modern performance and visual sophistication.

The final note

The Walker West Music Academy renovation exemplifies StellarCraft’s collaborative design, structural detailing, and metal fabrication expertise. StellarCraft’s Altair perforated panel façade system not only enhances the architectural character of the building but also celebrates the Academy’s cultural and creative legacy.