Perforated Panels

Altair

altair

Perforated Panels – Altair

Parking Garages / Building Façades / Architectural Elements

Altair Perforated Panels are cost effective, vertical support panels formed to created rigidity and strength to meet code for parking structures and building façades. Aluminum perforated metal patterns come in a variety of shapes and sizes for a truly unique façade. These cost-effective panels are lightweight, yet durable, and virtually maintenance free.

Parking Garages / Building Façades / Architectural Elements

Standard Options

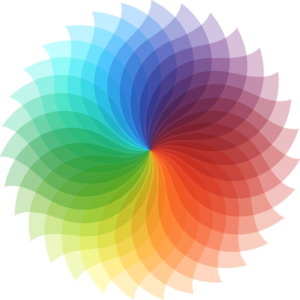

finishes – fluoropolymer coatings

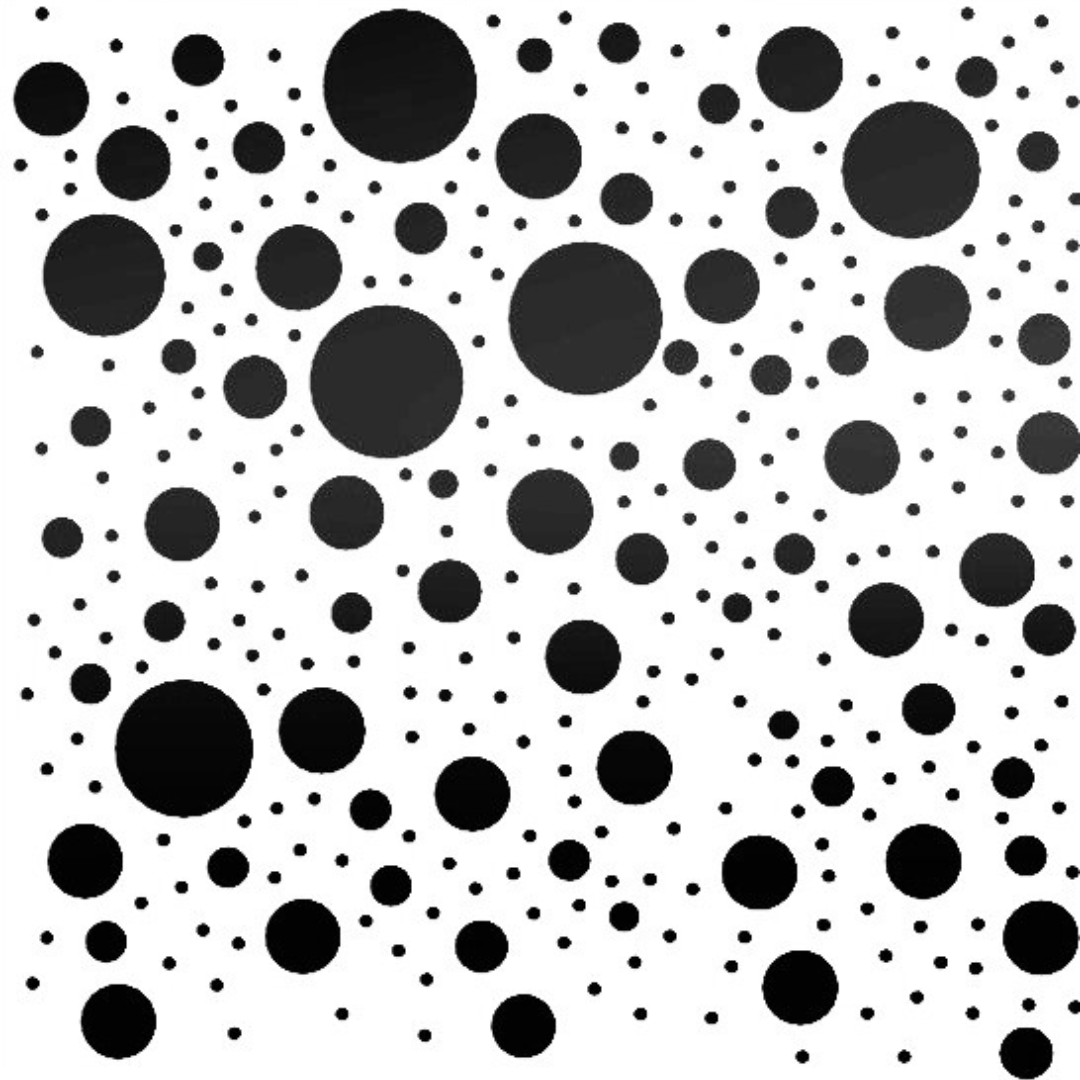

infill patterns

StellarCraft has 12 standard pre-engineered infill patterns and unlimited colors, textures and gloss finishes. Stellarcraft offers high-performance coatings with an extended gloss range that can create looks never before possible with powder, including mineral tones and textures that mimic cement, stone, teracotta and anodized metal.

If you do not see a pattern or finish you’re looking for, please contact us for more information. Dimensions for your product will be determined by your project’s specifications.

try it out

See How It Fits

standards

Standards & Codes

Design and manufacturing of the Altair Perforated Panels has been performed to meet or exceed relevant standards and codes.

International

Building Code

American Architectural

Manufacturers

Association

Minnesota State

Building Code

American Society

For Testing

And Materials

The Society

For Protective

Coatings

American

Welding Society

The Aluminum

Association,

Inc.

Americans with

Disabilities Act

Accessibility Guidelines

standards

Standards & Codes

International

Building Code

American

Architectural

Manufacturers

Association

Minnesota State

Building Code

American Society

For Testing

And Materials

The Society

For Protective

Coatings

American

Welding Society

The Aluminum

Association,

Inc.

Americans with

Disabilities Act

Accessibility

Guidelines

fabrication

Fabrication & Installation

measure twice, cut once

precision installation

The Altair Perforated Panels are pre-engineered systems with installation in mind. Our engineers have figured out the support structures and connection details for the panel system so all you need to do is plug and play. Our collaborative design process allows architects to focus on the aesthetics while we manufacture the results.

Download to view the panel system and connection details.

Technical Specifications

materials

■ Aluminum Tube Support Alloy: 6061-T6 Series, ASTM B221

■ Aluminum Plate Alloy: ASTM B209, 5052-H32

■ Exposed Fasteners: Button head screws or bolts, consistent with the fence design

■ Welding Electrodes: Complies with AWS requirements

■ Fasteners, Anchors & Inserts: 304 stainless

dimensions

■ Maximum Material Thickness: Not to exceed 0.314” (8mm)

■ Maximum Material Width: Not to exceed 60”

■ Maximum Material Length: Not to exceed 144”

■ Vertical Supports – Rectangular Tube: 6″ x 2″ x 0.125″

■ Angle Clips: 3″ x 3″ x 0.188″

structural performance

■ StellarCraft Altair Perforated Panels comply with IBC structural strength and dimensions.

■ Wind load ASCE-7/10 40PSF and 60PSF

■ Deflection of aluminum panels to be L/60 max. Deflection of panel framing members to be L/175 max.

■ Thermal Movements: Allow for thermal movements from ambient and surface temperature changes acting on exterior metal fabrications by preventing buckling, opening of joints, overstressing of components, failure of connections, and other detrimental effects.