In the world of manufacturing, selecting the right metal cutting technology can make all the difference in terms of cost, efficiency, and the quality of your final product. Let’s break down the Water Jet, Laser, and Punch Machine capabilities in a metal cutting comparison to find what machine is best for your job.

Take our QUIZ or keep reading to discover what machine is right for your job!

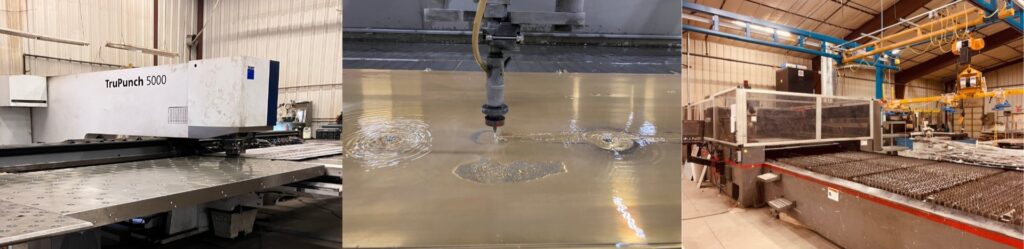

The Water Jet: Power Through Anything

Unmatched Material Versatility: The biggest strength of a water jet is its ability to cut virtually any metal you throw at it – including aluminum, steel, stainless steel, brass, copper, titanium, and exotic alloys like Inconel.

Thickness Champion: Need to slice through thick materials? Water jets excel here, often handling thicknesses up to a 12” or more.

No Heat, No Problem: Since it’s a cold-cutting process, water jet cutting doesn’t create a heat-affected zone (HAZ). This means the material’s properties remain unchanged, and you won’t have to worry about warping or heat distortion.

Edge Quality: Water jet cuts typically have a fine, sand-blasted finish. While generally good, you might need a secondary process for a perfectly smooth edge in some applications.

Time Considerations: Water jet cutting tends to be slower than laser cutting, especially when working with thinner materials. Cutting speeds can vary significantly depending on the material and its thickness.

The Bottom Line (Cost): Running a water jet comes with higher operating costs due to the wear on components and the necessity of consumables like abrasive garnet and specialized water treatment.

Best For:

- Thick materials

- Heat-sensitive materials

- Short production runs or prototypes

Laser Cutting: Precision and Speed in a Beam

Laser cutting utilizes a focused, high-energy laser beam to melt, burn, or vaporize material with remarkable precision.

Wide Range of Materials: Lasers are highly effective on many materials, including stainless steel and aluminum. Highly reflective metals can be challenging, and some materials may produce undesirable fumes when cut. Specialized fiber lasers are improving the ability to cut reflective metals.

Speed on Thin Stock: Laser cutting shines when working with thin materials, offering incredibly fast cutting speeds.

Edge Quality: Laser-cut edges are typically smooth and clean, often requiring minimal to no post-processing.

Time Considerations: Laser cutting is renowned for its speed, particularly on thinner materials. It’s often the fastest option for intricate designs in sheet metal.

The Bottom Line (Cost): Lasers generally have a lower operating cost than water jets. Their primary costs involve electricity and assist gases.

Best For:

- High-speed cutting of thin-gauge materials

- Intricate designs

- On applications where a clean, finished edge is crucial

The Punch Machines: The Repetitive Master

Punch machines use mechanical force to drive a punch through the material into a die, shearing out the desired shape.

Sheet Metal Specialist: Punching is primarily used for sheet metal fabrication of malleable metals like steel or aluminum.

Versatile Operations: Punch presses can hold multiple tools, allowing for a variety of operations like cutting different shapes, creating holes, and even performing shallow forming tasks in a single setup.

High-Volume Efficiency: For repetitive shapes and high production volumes, punching is exceptionally fast and efficient.

Edge Quality: The punch produces a quality edge that can be further smoothed via deburring, grinding, brushing or sand blasting.

Time Considerations: Punching is incredibly quick for creating repeated features, making it ideal for mass production.

The Bottom Line (Cost): While the machine cost can vary, the significant cost factor with punch machines is the tooling – each unique shape requires a specific punch and die. For high-volume runs, the per-part operating cost of punching is often the lowest due to its speed and efficiency.

Best For:

- High-volume production of sheet metal designs with repetitive features.

Water Jet vs. Laser vs. Punch Metal Cutting Comparison

Making the Right Choice for Your Project

So, which one is right for you? It all comes down to a few key questions:

What are you cutting? The type and thickness of your material will immediately narrow down your options.

How complex is your design? Intricate, detailed cuts might call for a laser or water jet, while simple, repeated shapes are perfect for a punch machine.

How many parts do you need? For a handful of prototypes, a water jet or laser is your best bet. For a large number of identical parts, a punch machine is the clear winner.

What’s your budget? Consider both the initial machine cost and the long-term operating costs.

The perfect choice for your project depends on what you’re cutting, the complexity of your design, the quantity of parts you need. By understanding the unique strengths of the water jet, laser, and punch machine metal cutting comparisons, you can make an informed decision. Are you ready to get started?

Check out our website, send us an email or give us a call today!