Who remembers the iconic 2000s slogan, “Got Milk?” In the metal fabrication world, we like to put our own spin on it — because these days, architects are constantly asking, “Got Specs?”

The answer? Absolutely!

Let’s dive into StellarCraft’s Altair Perforated Aluminum Panel specifications & what makes them stand out.

If you’re the type who loves the fine print, you can skip ahead and download the full specifications directly from our website [here]. Or, you can enjoy an hour’s worth of got milk? ads from 1993-present [below 👇]

Engineered for Strength and Performance

Every panel is manufactured to meet rigorous industry standards, including ASTM, AAMA, and AWS specifications. Built from 5052-H32 aluminum, our perforated panels offer superior strength and corrosion resistance while maintaining a lightweight, easy-to-install design.

Each system is engineered to perform under demanding environmental conditions:

- Wind Load Capacity: Up to 60 PSF (per IBC and ASCE-7/10 standards)

- Deflection Control: L/60 for panels and L/175 for framing members

- Thermal Movement Resistance: Designed for up to 180°F temperature variance

These performance criteria ensure that every installation maintains structural integrity and aesthetic quality — even in extreme climates.

Custom Perforation Options

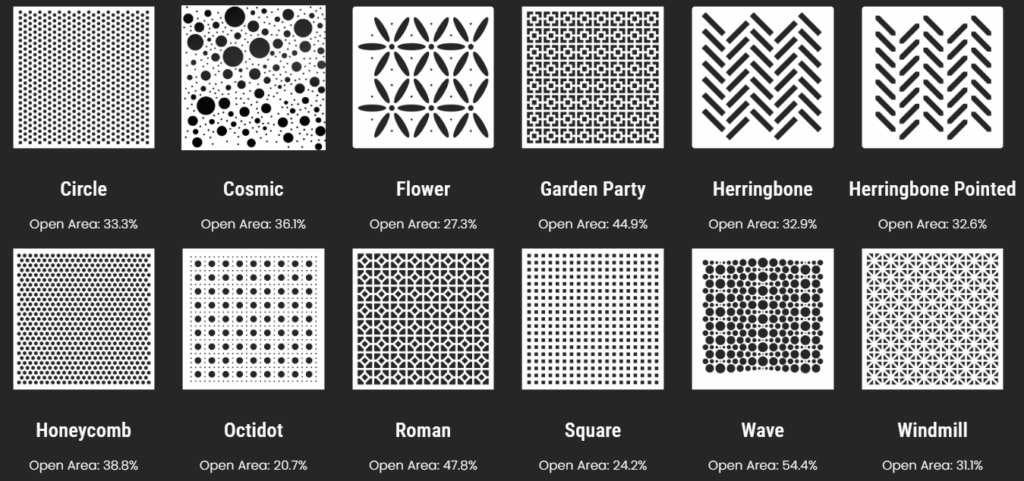

Perforation design is what sets each project apart. StellarCraft offers customizable perforation shapes, sizes, and spacing to meet both functional and architectural goals.

- Material Thickness: 0.125″–0.1875″ aluminum plate

- Maximum Panel Size: Up to 46″ in height and length (depending on thickness)

- Perforation Styles: Choose from standard or custom perforated patterns

With our advanced CNC punching and CAD capabilities, we can create intricate, repeatable patterns and custom designs such as lettering, logos, or branding elements — that bring architectural concepts to life.

Durable Finishes Built to Last

StellarCraft applies only the highest-quality finishes to ensure long-lasting color and protection.

Choose from:

- AAMA 611 Anodized Coatings – for a clean, metallic aesthetic with excellent corrosion resistance

- AAMA 2604 or AAMA2605 High-Performance Organic Coatings– for maximum UV stability, color retention, and weathering performance

Each finish is available in a range of colors, gloss levels, and textures to meet your design intent. Perforated aluminium panels are carefully protected during shipment and installation to preserve their quality and appearance.

Perforated Aluminum Panel Installation

Our systems are designed for precision fit and ease of installation:

- Prefabricated aluminum panels with integrated mounting components

- Flush countersunk fasteners and clean edge detailing

- Compatibility with concrete, steel, or aluminum framing systems

- Optional nylon or non-conductive gaskets to prevent galvanic corrosion

Every detail — from pre-drilled anchor points to welded terminations and curved panel options — is fabricated to ensure consistent alignment and seamless integration with the surrounding architecture.

Applications

Our perforated aluminum panels are ideal for:

- Architectural screening and façades

- Parking structure enclosures

- Decorative interior wall features

- Custom branding or logo applications

Partner with StellarCraft

As a U.S.-based fabricator with decades of expertise, StellarCraft provides complete design-to-installation support. From CAD modeling to precision cutting, finishing, and packaging, we deliver consistent quality and architectural excellence on every project.

If your next project calls for custom perforated facades or architectural metal systems, our team is ready to help you achieve your design vision — down to the last detail.

Contact StellarCraft to request specifications, CAD details, or a custom quote today.