Creating a guardrail spec can feel overwhelming. With so many industry opinions and options, the “shoulds” and “should-nots” often get muddled in the nitty-gritty of compliance and application. Most mistakes aren’t due to a lack of knowledge, but rather professional overconfidence, tight deadlines, and communication breakdowns between teams.

Let’s break down 5 D’s of common guardrail spec mistakes. No, not Dodge, Duck, Dive, Dip, and Dodge, but rather Disregard for Local Building Codes, Deficient Material Selection, Damage from Corrosion, Defective Fastened Systems, and Disconnection.

The 5 D’s of Common Guardrail Spec Mistakes

1. Disregard for Location Building Codes - Neglecting Local Building Codes and Regulations

The Mistake: Creating a guardrail spec that fails to adhere to local building codes for crucial elements like height requirements, baluster spacing, material standards, and load requirements. This can lead to costly rework and safety hazards.

How to Avoid It: Always prioritize code compliance. Adhering to all relevant codes prevents timeline setbacks and faulty structural design. All Stellarcraft products meet the International Building Code (IBC) and American Welding Society (AWS) code requirements. Depending on your installation location, other codes, such as the Universal Building Code (UBC) or specific state and city codes, will also apply.

2. Deficient Material Selection - Improper Material Selection

The Mistake: Choosing materials in your guardrail spec that aren’t suitable for the surrounding environment of the application, considering factors like element exposure, high-traffic areas, or building height.

How to Avoid It: We recommend aluminum for its exceptional durability and lightweight properties, making it ideal for withstanding significant weight and wind load forces. While naturally corrosion-resistant, aluminum can also be anodized or powder-coated to further enhance its longevity and aesthetic appeal.

3. Damage from Corrosion - Improper Coatings

The Mistake: Improper coating application, which leads to premature corrosion of the guardrail system.

How to Avoid It: Specify a paint coating approved by the American Architectural Manufacturers Association (AAMA). The leading industry paint coatings, AAMA 2604 and AAMA 2605, offer superior protection. Astro provides these coatings with up to a 10-year warranty.

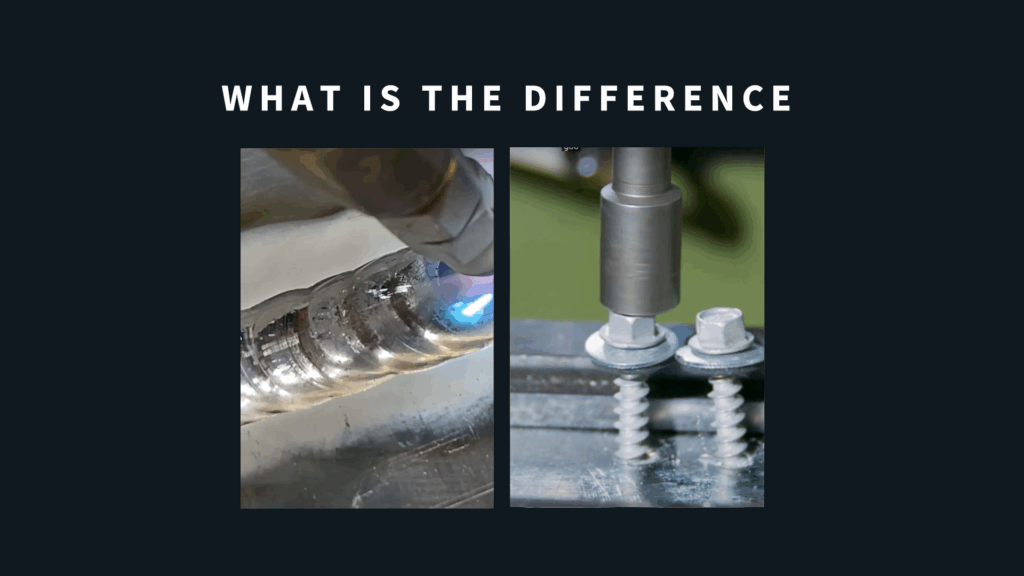

4. Defective Fastened System - Lack of Knowledge

The Mistake: Fastened guardrails are prone to a range of issues, including galvanic corrosion, damage to connections from weight load stress, vulnerability to vandalism, and potential faulty manufacturing. If you do not work with a manufacturer and installer that you trust, your fastened system may fail over time.

How to Avoid It: Work with a fabricator and and installer who understands the risks of fastened systems and knows how to prevent failures. OR choose a completely welded guardrail system. Welded guardrails are fabricated from the same material, significantly reducing the risk of galvanic corrosion. They are fabricated with permanent joints that are chemically bonded together to uphold load requirements. At Astro, our welded guardrails adhere to strict welding codes, with the entire process overseen by a Certified Welding Inspector.

5. Disconnection - Poor Communication and Coordination

The Mistake: Without regular check-ins and strong communication between the fabricator and architectural teams, potential problems often go unnoticed. Rushing the design phase, failing to finalize the vision, or neglecting intricate details can lead to costly and time-consuming changes.

How to Avoid It: Don’t hesitate to seek clarification. At Astro, our proven process emphasizes continuous communication at every checkpoint. Our project managers believe in open and transparent collaboration, actively incorporating feedback into the design. This core value guides us throughout every project, ensuring a smooth and successful outcome.

We Make Metal Perform - From Concept to Completion

Specifying guardrails, while seemingly straightforward, can become a complex endeavor with a multitude of industry opinions and options. At Astro we streamline the guardrail spec process by partnering with you from design conception to project completion.